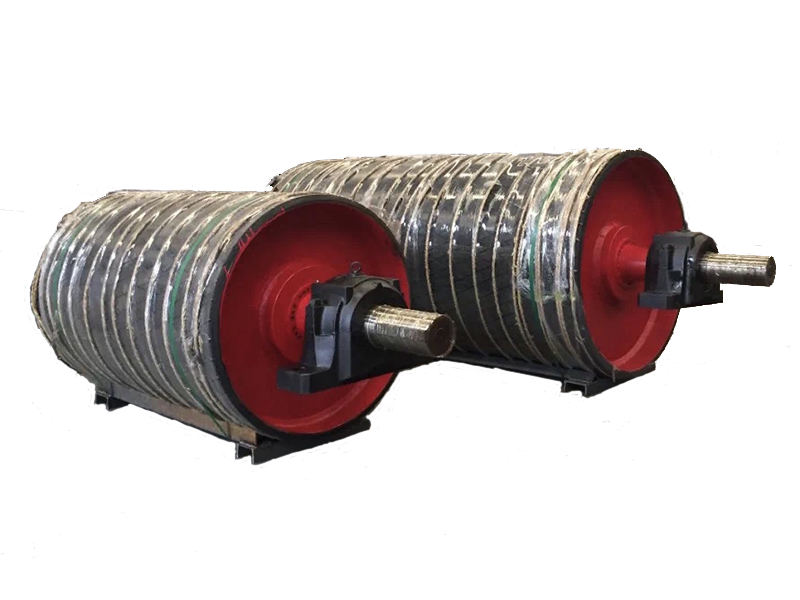

Drive pulley parameters

| B | D | A | L | L1 | L2 | K | M | N | Q | P | H | h | h1 | d | b | ds | Rolling shaft model | Torque allowed(kg*mm) | |

| Smooth surface pulley | Rubber Coated pulley | ||||||||||||||||||

| 500 | 500 | 850 | 600 | 1097 | 505.5 | 115 | 70 | - | 280 | 340 | 33 | 33 | 60 | 55 | 16 | 27 | 1312 | 16300 | 25000 |

| 600 | 500 | 100 | 750 | 1280 | 588.5 | 135 | 90 | - | 350 | 210 | 33 | 33 | 76 | 70 | 20 | 27 | 1316 | 21200 | 32600 |

| 630 | 29600 | 45400 | |||||||||||||||||

| 800 | 500 | 1300 | 950 | 1580 | 738.5 | 135 | 90 | - | 350 | 410 | 33 | 33 | 76 | 70 | 20 | 27 | 1316 | 26200 | 40100 |

| 630 | 1661 | 771 | 175 | 130 | 80 | 380 | 460 | 33 | 33 | 95 | 90 | 25 | 3520 | 36700 | 56100 | ||||

| 800 | 55900 | 85500 | |||||||||||||||||

| 1000 | 630 | 1500 | 1150 | 1861 | 871 | 175 | 130 | 80 | 380 | 460 | 33 | 33 | 95 | 90 | 25 | 27 | 3520 | 45700 | 70100 |

| 800 | 1945 | 900 | 215 | 160 | 90 | 440 | 530 | 53 | 53 | 119 | 110 | 32 | 34 | 3524 | 69600 | 106800 | |||

| 1000 | 2020 | 930 | 255 | 170 | 100 | 480 | 570 | 53 | 53 | 140 | 130 | 36 | 3528 | - | 177500 | ||||

| 1200 | 630 | 1750 | 1400 | 2195 | 1025 | 215 | 160 | 90 | 440 | 530 | 53 | 53 | 119 | 110 | 32 | 34 | 3524 | 54900 | 84000 |

| 800 | 83700 | 128100 | |||||||||||||||||

| 1000 | 2270 | 1055 | 255 | 170 | 100 | 480 | 570 | 53 | 53 | 140 | 130 | 36 | 3528 | - | 213000 | ||||

| 1250 | 2305 | 1065 | 275 | 180 | 110 | 540 | 630 | 53 | 53 | 161 | 150 | 40 | 3532 | - | 300000 | ||||

| 1400 | 800 | 2000 | 1600 | 2445 | 1150 | 215 | 160 | 90 | 440 | 530 | 63 | 63 | 119 | 110 | 32 | 34 | 3524 | 97600 | 149200 |

| 1000 | 2555 | 1190 | 275 | 180 | 110 | 540 | 630 | 63 | 63 | 161 | 150 | 40 | 3532 | - | 249250 | ||||

| 1250 | - | 350000 | |||||||||||||||||

| 1400 | 2635 | 1200 | 335 | 200 | 120 | 590 | 680 | 63 | 63 | 181 | 170 | 40 | 3536 | - | 470000 | ||||

Minimum drum diameter under stable conditions

| Diameter of drive pulley | Minimum diameter | ||||||||

| Maximum tension utilization | |||||||||

| >60%~100% | >30%~60% | ≤30% | |||||||

| Pulley mode | Pulley mode | Pulley mode | |||||||

| A | B | C | A | B | C | A | B | C | |

| 500 | 500 | 400 | 315 | 400 | 315 | 250 | 315 | 315 | 250 |

| 630 | 630 | 500 | 400 | 500 | 400 | 315 | 400 | 400 | 315 |

| 800 | 800 | 630 | 500 | 630 | 500 | 400 | 500 | 500 | 400 |

| 1000 | 1000 | 800 | 630 | 800 | 630 | 500 | 630 | 630 | 500 |

| 1250 | 1250 | 1000 | 800 | 1000 | 800 | 630 | 800 | 800 | 630 |

| 1500 | 1600 | 1250 | 1000 | 1250 | 1000 | 800 | 1000 | 1000 | 800 |

Delivery